The evolution of electronics has changed the way humans live their lives from reliable smartphone acting as a personal assistant to the airplanes bringing crowds to different destinations daily. It’s incredible how electrons – tiny particles in atoms carrying electrical energy – have been used to manipulate machines and process information to usher progress. Electronic manufacturing became a viable industry due to the increasing demand for circuit boards, microchips, and other general electronics to feed into the world’s dependency on technology. No other sector experiences upheavals and changes quickly due to short product life cycles and sales. To remain competitive and relevant, electronic companies must also ask themselves the following questions besides where to procure long-lasting manufacturing equipment online.

1. How can I ensure production and delivery in times of crisis?

Supply chains can easily be disrupted in times of catastrophe both locally and internationally, whether its geopolitical uncertainty, cyber-attacks, or a sudden disease outbreak like the COVID-19. Tech companies, apparel makers, and industrial-equipment manufacturers are most vulnerable in the COVID-19 epidemic as most inputs are sourced from China and Southeast Asia. While costing more in the short term, diversification efforts such as having additional suppliers in other countries, shortening supply chains, and maintaining a large inventory can ensure business continuity and protect companies from being paralyzed.

2. How can I continuously innovate to meet demand?

New lines of smartphones are being released almost every year, prompting consumers to trade in their old devices for the latest model. Electronic manufacturing companies are required to adapt to the fast pace of advancing electronics requests with flexibility. Products need to launch on time at optimal conditions – volume, price, and quality. It is then imperative to move away from processes driven by manual tasks toward automation and artificial intelligence.

3. What are my protocols on quality control, service, and warranty?

Quality control is a top-level priority in the production process, given its impact on the company’s reputation, cost, and success. A flawed quality assurance system can result in wasted resources, human errors, and failed product specifications. However, despite having a detailed and strict quality engineer on board, mistakes can still happen. Companies must be ready with a service and warranty protocol that won’t endanger the bottom line and keep customers happy. They can consider incentivizing servicing faulty parts than replacing products under warranty.

4. Are my processes and products environment-friendly and energy-efficient?

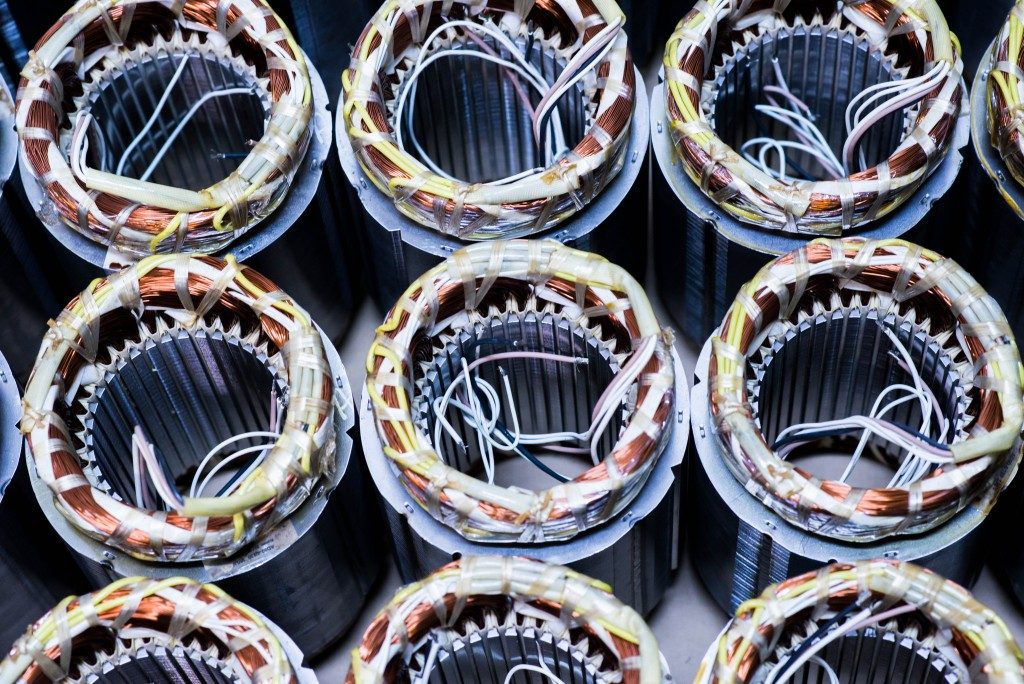

Conversations surrounding e-waste and energy efficiency are becoming regular due to climate change. Electronics contain materials like copper and aluminum, and when burned releases chemicals harmful to humans and the environment. Standards and regulations are being drafted and implemented that require electronics manufacturers to be accountable for the environmental impact of their product. All aspects of the product’s life cycle must be revisited and optimized, which includes the manufacturing process, raw materials, energy use by the consumer, and the disposal mechanisms. Some E-waste mitigation policies can be found here.

The evolving technological landscape entails constant innovation from electronics manufacturing companies as issues in the supply chain, demand, quality control, and climate change become prevalent. Sitting on one’s laurels and keeping to the status quo might spell disaster to the company.