- Explore a career in manufacturing by considering roles such as a production manager or quality control inspector.

- Industrial engineers improve manufacturing processes by enhancing efficiency, reducing waste, and ensuring quality.

- Augment your skillset with soft skills that make people amicable and easy to talk with.

- Success in manufacturing depends on making informed choices and committing to continuous personal and professional development.

The manufacturing sector is the backbone of modern industry. Yet, for many, it remains a mystery shrouded in the sound of machines and the rustle of countless moving parts. With the world of making constantly evolving, there’s never been a better moment for students and young professionals to explore the avenues of this dynamic field. This guide will unveil what it takes to survive and thrive in manufacturing.

Mastering the Core Elements of Manufacturing

Manufacturing might be an umbrella term covering diverse industries, from automotive to textiles, but specific foundational skills are universally valuable.

Establish a Solid Educational Background

A field relevant to manufacturing, such as engineering or business management, equips you with the intellectual resources to make good decisions. A degree program focused on these areas prepares students to navigate the intricacies of production, quality control protocols, and logistics management.

Knowledge Transfer

Most roles within manufacturing require a solid foundation in the technical aspects of production, quality control, and safety regulations. Academic learning partnered with real-world application is a skill gained from mastery of subject matter. Equipping yourself with the necessary technical skills will be a robust base for any path you choose within this sector.

Develop Practical Skills

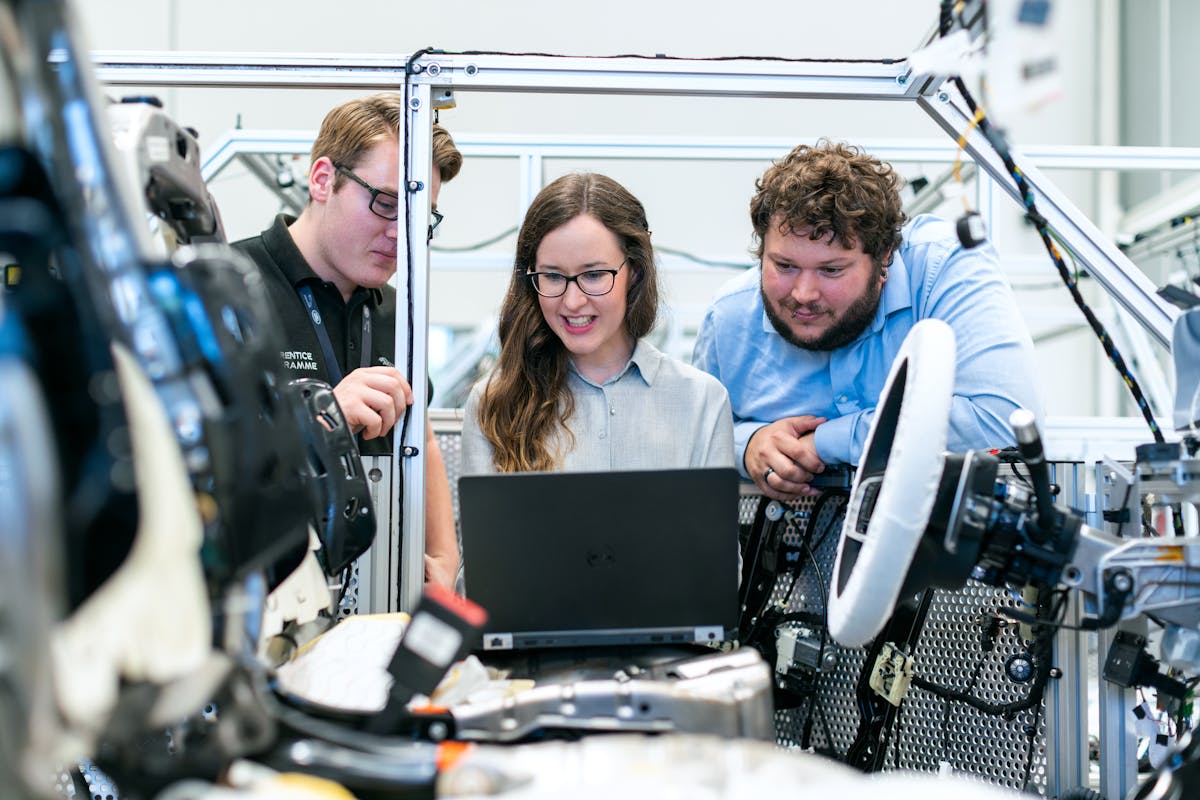

Exposure to the manufacturing environment through internships or co-op programs can provide the practical experience that employers seek. Make the most of any opportunities to work on projects that require collaboration across different departments. The richer your project portfolio before you enter the job market, the better.

Look for Opportunities Right Away

The mantra of ‘seek knowledge first’ is integral to thriving in the manufacturing landscape. Begin by seeking out opportunities — not only to learn but also to earn.

Gaining work experience early on is crucial. Look for entry-level positions or internships in manufacturing firms, which can often lead to full-time roles upon graduation. Even if a particular role seems menial, remember that there are lucrative career opportunities in the manufacturing industry that can provide hands-on experience and valuable insight into the operations.

Balancing experience with income is a delicate art, especially if you’re juggling student loans or other financial responsibilities. Part-time work during school or freelance opportunities can support you financially while helping to broaden your skill set. Employers value candidates with a record of commitment, dedication, and hustling for paid work in their field.

The Importance of Soft Skills

Technical prowess is only part of the winning formula in manufacturing. Soft skills, often overlooked in pursuing certification and specialization, are gaining importance.

Effective Talk with Colleagues

Collaborating effectively is invaluable in an industry where teamwork is critical and cross-functional communication can make or break a project. This is particularly true in roles like supply chain management, where you must coordinate with vendors, customers, and internal departments to ensure the smooth flow of materials and resources.

Empower Employees Through Responsibility

Leadership is another soft skill that should be honed. Manufacturing environments are hierarchical, and the capacity to lead is not just a boon for management roles. Leadership also manifests in taking initiative, solving problems independently, and motivating others to strive for excellence.

Continuous Improvement

Adaptability is perhaps the most essential soft skill in a sector marked by rapid change. The manufacturing industry must constantly adapt to global dynamics to stay on top. Being open to new ideas, methodologies, and technologies will also be as critical to your success as your technical expertise.

Career Paths and Opportunities in Manufacturing

Manufacturing offers a diversity of career paths tailored to different strengths and interests.

Production Personnels

A production manager, for instance, oversees the day-to-day operations of manufacturing plants, ensuring that deadlines are met and products meet quality standards. This might be your path if you have a knack for planning and overseeing complex projects.

Quality control inspectors are crucial in manufacturing, checking products for defects and ensuring they meet industry standards and regulations. The attention to detail of an inspector can often make a critical difference in customer satisfaction and market reputation.

Infrastructure and Analysts

Industrial engineers are:

- The architects of efficiency in the manufacturing process.

- Focused on reducing waste.

- Optimizing workflow.

- Improving quality.

This role holds significant promise for mathematically inclined people who enjoy problem-solving.

Supply chain analysts ensure that goods are manufactured and delivered efficiently to customers, focusing on minimizing inventory costs and ensuring timely deliveries. Analytical skills and a strong business background are particularly beneficial for this role.

The path to success in manufacturing is not a predetermined route but a series of choices and preparations that will mold you into a competitive and in-demand professional. By walking through the steps outlined in this guide and by remaining persistent and open to growth, you are well on your way to crafting a rewarding career in the dynamic realm of manufacturing.